| Rooftiles, Chimney, and examination of our utility cupboard. |

We got our temporary woodstove |

Finished horizontal support beams on the east side

This week we started on the preparations for our facade. We are planning for vertical planks on top of horizontal beams. We want to be able to open our doors wide open.

Monday 21 September

Today we worked from home due to Corona. No difference there. Perhaps the difference is that it is not going well in the Netherlands. The R-value is currently 1.34, meaning that every person with Corona is carrying it to 1.34 other people so that in two weeks, ten thousand people will carry Corona. Some will die; some will get chronic deceases. I do not want to be one of these people.

We spoke with the building company about the concrete plates under the wood above the foundation. Our plan is doable—the horizontal wood beams we need for behind the exterior red planks need to be estimated. When he has this information, then we will get to hear how much it will cost and when they deliver it. They primarily called me to ask when they can pick up their generator. It is funny this is happening right now after I had such a fight with our generator.

In the evening, I mounted the next level of horizontal beams. The generator started, and it was great fun to work on this. I sawed the smallest possible openings in the vertical bars so that we could mount horizontal bams. Later in the week, we decided to remove as much as possible of all vertical beams to improve ventilation, but more about that later. My wife worked on the isolation and processed one new package of isolation. We stopped the work when it became too dark. While gathering tools, the sun settled behind the horizon. Another day had ended. We went home, and I published last week’s blog.

In the evening, I mounted the next level of horizontal beams. The generator started, and it was great fun to work on this. I sawed the smallest possible openings in the vertical bars so that we could mount horizontal bams. Later in the week, we decided to remove as much as possible of all vertical beams to improve ventilation, but more about that later. My wife worked on the isolation and processed one new package of isolation. We stopped the work when it became too dark. While gathering tools, the sun settled behind the horizon. Another day had ended. We went home, and I published last week’s blog.

Tuesday 22 September

Today we had a lunch walk in the neighborhood for the first time in a very long time—just a short walk. The weather was beautiful.

I calculated how much of the horizontal beams we will need. That is 551 meters. It takes a surprising amount of calculations to find out. I estimated that the beams would be 60 centimeters apart. There is extra necessary above and below the windows to support the horizontal planks. There is a beam needed at the top of the wall as well not included in the calculation. I did not remove the beams for the windows either, so perhaps one balance out the other.

I calculated how much of the horizontal beams we will need. That is 551 meters. It takes a surprising amount of calculations to find out. I estimated that the beams would be 60 centimeters apart. There is extra necessary above and below the windows to support the horizontal planks. There is a beam needed at the top of the wall as well not included in the calculation. I did not remove the beams for the windows either, so perhaps one balance out the other.

We went to the new house in the afternoon, and it was going to be the final of the excellent weather for a long time. It was feeling a bit sad that hereafter we will not be standing on the scaffold in the T-Shirt in the evenings and see the sun go down. Besides, it will get dark earlier, so there will soon be no window of opportunity to work without electric lights in the evenings. It is like we are in a race between the sunset time and the arrival of electricity in our house. As it feels now, the sunset time will win.

Wednesday 23 September

Today I had a half-day off that we decided to use that for building at the new house. Are you surprised by that? It still feels new with free time on Wednesday afternoon. I texted the building company that we were at the site. I told them it was convenient to get their generator today. We were also supposed to get a spare wood-stove delivered by our wood-stove specialist this afternoon, but that did not happen.

Today I had a half-day off that we decided to use that for building at the new house. Are you surprised by that? It still feels new with free time on Wednesday afternoon. I texted the building company that we were at the site. I told them it was convenient to get their generator today. We were also supposed to get a spare wood-stove delivered by our wood-stove specialist this afternoon, but that did not happen.

We worked on our tasks. I put up horizontal beams, and my wife isolated the ceiling of the ground floor. In the late afternoon, the building company showed up to pick up their generator. They spotted our horizontal beams, and they were not enthusiastic about this construction. It was The Netherlands meets Sweden, and I explained our considerations. I could do that because we spent a good deal of time to get it right. We iterated our pros and cons, but it did not bite. We are the customers, obviously, and we do what we want but nevertheless. I think it was also a lesson for them to listen to the needs of the customers because we have been clear from the very first moment about what we want, and they agreed to deliver that, but perhaps they did not listen carefully.

After they left, I checked out how this is done in Sweden, and we are fine. We do it like they do in Sweden. Behind the vertical outer planks, you have horizontal beams, just like that, and not two layers of beams. In Sweden, there is one layer of horizontal beams like we have it. Since we also got the outer planks not next to each other but staggered with room for ventilation, we are double excellent regarding ventilation, everything is fine. Although we are doing well from a Swedish perspective, this leaves a little sour feeling. We had liked to be “approved” by our Dutch builder as well. They were very impressed with our isolation work, so that was nice. I also sensed they had not realized all the implications of the construction, and this perhaps hurt their feelings. In the building industry, there are always 50 ways of doing the same thing. No exceptions. Also, here, in this case, there are several ways.

While we talked to the building company, it started to rain.

It was no fun to climb the scaffold when it was wet. Instead of sitting down on wet planks and working on the house, I decided to undo changes to the scaffold that the roofers had done.

Thursday 24 September

The rain continued on Thursday but stopped in the afternoon. When we came to the new house, it had rained 11 millimeters. There had been digging activities at our Mrs. PMT today. They had removed the southwest corner post of our plot. Since I had put out bamboo sticks in a straight line, I could reestablish the corner post again, but I wouldn’t say I like it. This time I took a sturdy beam. I draped it in barrier tape. At this phase, it is so easy to use a little of someone else’s plot. Then a little more and so on. I will be restoring that barrier tape every other day if that is what it takes. If someone needs access to our plot, then it is always possible to ask. Then we can talk about it. I removed a heap of pipes that someone had placed on our ground.

It is colder now. Just like I had predicted. It is different to think about how things will be in the future compared with experiencing it. The chill weather was colder than I had anticipated. Still, we went to the new house and worked on our tasks. My wife was making significant progress and isolated away another package of isolation. She processed one full tower of isolation material, and from here, there are three more towers to go.

I put out a little cloth on the wet planks of the scaffold and continued working on sawing the beams for the horizontal replacement. I found out if there is a nail straight through the line where I need sawing, it is perfectly acceptable to saw next to it. There are not so many beams left until I reached the top of the house. You might wonder why I am not just removing the vertical and replace them with horizontal. The problem with that approach is that I will damage the foil too much. Then I will have to replace the foil as well, and that is too much. I stopped working when it got too dark.

I put out a little cloth on the wet planks of the scaffold and continued working on sawing the beams for the horizontal replacement. I found out if there is a nail straight through the line where I need sawing, it is perfectly acceptable to saw next to it. There are not so many beams left until I reached the top of the house. You might wonder why I am not just removing the vertical and replace them with horizontal. The problem with that approach is that I will damage the foil too much. Then I will have to replace the foil as well, and that is too much. I stopped working when it got too dark.

When we got home, I worked on the ventilation and sewage plan. I am doing that in Fusion 360. Autodesk has announced that they will restrict the personal license on 1 October. I think I will need to finish this plan before then.

Friday 25 September

Today we worked from home. I could see no reason to work from the office today. The R-value in the Netherlands is still over 1. There are no signs that people will change their behavior, so this will be a dramatic problem. After work, we decided to rest instead of going to the house and build. It was nice to have a free evening.

Saturday 26 September

The rain gauge had collected 4 millimeters of rain. It was a beautiful morning. It took until midday before I got started working, though. It held up until the evening before it started raining again.

My wife started isolating, and I continued on the east side of the house. I put up the beam above the windows on the first floor, and with that, it was time for the top of the wall. I figured it was best to put up the diagonal beams first and then continue on the horizontal.

We had a break to look at our neighbor’s project on the east side of the house. They are building a tiny house where they will be living while they are building their real house. Right now, they have the foundation of the tiny house. They covered it with orange tarp against rain. When it is dry again, they will continue with the building project. I can see them from our scaffold. They tell us that the walls will arrive on a trailer in a couple of weeks or already next week. They asked about our project, and I told them about our horizontal beams.

We had a break to look at our neighbor’s project on the east side of the house. They are building a tiny house where they will be living while they are building their real house. Right now, they have the foundation of the tiny house. They covered it with orange tarp against rain. When it is dry again, they will continue with the building project. I can see them from our scaffold. They tell us that the walls will arrive on a trailer in a couple of weeks or already next week. They asked about our project, and I told them about our horizontal beams.

We will continue applying horizontal beams, but we will remove more of the remaining vertical beams. This way, air can travel horizontally between the horizontal beams. If we don’t do this, we get square pockets. And this is a little adjustment to our plan, and it required that we cut away some of the vertical beams. Or daughter that came to help us today worked on this task while I continued on the top part of the wall. On the northeast side, there were no problems, but on the southeast side, there was a strange hump. I cut the foil open and found a screw that had missed the target by 5 centimeters. I decided to cut it off with the angle grinder. Usually, that would be no problem at all!

We will continue applying horizontal beams, but we will remove more of the remaining vertical beams. This way, air can travel horizontally between the horizontal beams. If we don’t do this, we get square pockets. And this is a little adjustment to our plan, and it required that we cut away some of the vertical beams. Or daughter that came to help us today worked on this task while I continued on the top part of the wall. On the northeast side, there were no problems, but on the southeast side, there was a strange hump. I cut the foil open and found a screw that had missed the target by 5 centimeters. I decided to cut it off with the angle grinder. Usually, that would be no problem at all!

Our generator did not start. It did not cough. It spins, but it feels like the transmission with the engine is completely lost. How is that possible? Well, with this engine, it is possible because everything breaks and falls apart by itself. It was a remarkably terrible choice to buy this generator. It is not even worth the money I paid for it. I removed the sides with the decals so that I got access to the screws holding the tank. The tank can slide out under the bars, and with that, the engine is visible. The problem was not visible, though.

Our generator did not start. It did not cough. It spins, but it feels like the transmission with the engine is completely lost. How is that possible? Well, with this engine, it is possible because everything breaks and falls apart by itself. It was a remarkably terrible choice to buy this generator. It is not even worth the money I paid for it. I removed the sides with the decals so that I got access to the screws holding the tank. The tank can slide out under the bars, and with that, the engine is visible. The problem was not visible, though.

We talked about different options we got:

- Try to repair the engine, ourselves.

- Try to repair the engine with the help of experts. Where are they?

- We can wait. Just leave the engine as it is until we got electricity in the house. Do other things. Gardening, learn another language?

- Leave the engine until we get electricity in the house but continue working using only hand tools. Do we need to get these hand-tools?

- We can try to borrow a replacement engine from a neighbor. Well, they all need their generators as much as we do.

- We can rent a replacement engine. Since we don’t know beforehand when we get electricity, this can become an expensive option.

- We can buy a replacement engine. Buy an engine of around 500 euros. Then we got two of these machines. In the best-case scenario, both are useless to us in five weeks when we got our electricity.

- We can buy battery-driven machines and charge these at home, around 500 euros. With this, we could work in a fossil-free way, and since we are convinced that it is essential to avoid unnecessary CO2 emissions, this would be a practical option.

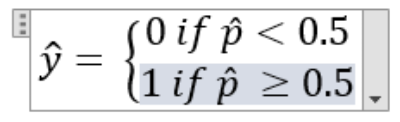

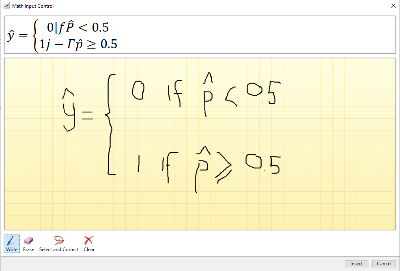

At first glance, option number 8 sounds promising. But how long time can you use the machine? For that, we found the formula.

First, divide the wattage of the machine by the voltage. The result is ampere. Now take the ampere-hour score of the machine and divide it with the ampere number you just calculated. Now you know how many hours the machine can run on full throttle. Multiply with 60 to get minutes.

We calculated that a top-notch saw with built-in led light would work 8 minutes. That is not too much.

With that, the first option did not sound so convincing anymore. It was not feeling so funny this situation, but tomorrow is another day. We will have a look at the generator again.

Another issue with not having a generator is that when we have other people working in the house for us, then we cannot possibly require all of them to use only battery equipment. If we went that route, then our electrician and plumber cannot do their work. The whole project would come to a standstill for the next 5 to 7 weeks. That is a little bit too much.

Sunday 27 September

Sunday 27 September

I had no idea what option we would end up deciding on. We would start working on option 1. But first, I noticed I had forgotten the ear protection hanging on the scaffold. Can you see it too? It had rained 14 millimeters last night, and the cups of the ear protection had collected some of that as well. The building fence around the house is populated with bitter vetch. It will be a little annoying to get rid of the plants. Not our problem.

I had no idea what option we would end up deciding on. We would start working on option 1. But first, I noticed I had forgotten the ear protection hanging on the scaffold. Can you see it too? It had rained 14 millimeters last night, and the cups of the ear protection had collected some of that as well. The building fence around the house is populated with bitter vetch. It will be a little annoying to get rid of the plants. Not our problem.

Full of enthusiasm, we started on option one of our list of possible solutions. I already started dismantling the parts yesterday. Today I removed the housing around the ventilation of the motor. Perhaps I would find any information there. I figured that it was about time to check the oil level of the machine. For that, I had to construct a funnel, and I made mine of a coca-cola can that someone left at our driveway. I filled up the oil to a proper level. So far, I found these defects:

Full of enthusiasm, we started on option one of our list of possible solutions. I already started dismantling the parts yesterday. Today I removed the housing around the ventilation of the motor. Perhaps I would find any information there. I figured that it was about time to check the oil level of the machine. For that, I had to construct a funnel, and I made mine of a coca-cola can that someone left at our driveway. I filled up the oil to a proper level. So far, I found these defects:

- The fuel pipe needs to be replaced because it has cracks. That is not good. It can leak, and air can get in, essential.

- Replace the spark plug to a new one without my modifications. Nice to have but not essential.

- The spark plug cable has chips falling off, not essential, but nice to have.

- The start-cord housing. The drum that should wind up the cord has lost chips so that the cord can fall off and unwind on the running motor. Essential.

After I established this wish list of things to replace, we also understood we could not get this on a Sunday.

The telephone number of the man we bought the machine from did not work anymore. His name does not exist in the telephone guide. Searched the logotype of his company and found it came from a university in Casablanca, or it came from a Russian software package?

In my search tonight, I found that the generator is supposed to stop if the oil level gets too low. Can it be so that if I put the stuff back, then will work again? I have no clue.

For today, option 4 was not so bad. We went to a hardware store and bought a hammer and a crowbar. With this, we finished the preparations on the east side. But how did it go with the bolt that was sticking out? I made an opening in the beam for the bolt! Below the scaffold, we dropped discarded pieces of vertical bars. I mounted new horizontal bars.

For today, option 4 was not so bad. We went to a hardware store and bought a hammer and a crowbar. With this, we finished the preparations on the east side. But how did it go with the bolt that was sticking out? I made an opening in the beam for the bolt! Below the scaffold, we dropped discarded pieces of vertical bars. I mounted new horizontal bars.

I am pleased with the result. Now we can start putting up the vertical planks. Behind the planks, there is enough space for ventilation. Since the planks will be mounted staggered, meaning there will be ventilation because of that way as well. The doors will be possible to open. This building method is also used in Sweden. With this method, we ticked all our required checkboxes. Perhaps we also ticked a checkbox of hurt feelings of our builder, but it is our house, and they could have delivered it with horizontal beams as well.

I am pleased with the result. Now we can start putting up the vertical planks. Behind the planks, there is enough space for ventilation. Since the planks will be mounted staggered, meaning there will be ventilation because of that way as well. The doors will be possible to open. This building method is also used in Sweden. With this method, we ticked all our required checkboxes. Perhaps we also ticked a checkbox of hurt feelings of our builder, but it is our house, and they could have delivered it with horizontal beams as well.

As you can see, the holes in the foil are covered with the special tape. We will need more of that tape, but we found that in a local hardware store, so it is just a question of buying more when that is needed. We gathered the pieces that we dropped on the ground.

The problems with electricity suck, though. Now, if we had electricity, we would have started with red planks. Now I don’t know what to do. I think it is best to put back the pieces of the generator as quickly as possible to get it running. I hope that the engine got an oil pressure protection that kicked in and stopped the engine when the oil level got low. That would be magic.

This story ends with a kind of cliff hanger. What option will we follow for fixing the failed generator? How will the examination of the cupboard go next Wednesday?

(Before I published this blog I modified my Docx2html converter so that it resize images with antialiasing. It looks much better. Before I used OpenCV of Python and now I switched to Pillow)

The west wall of the barn was paintedStarted preparing for painting the barnFinished plastered all walls of the barnStarted plastering the wallsBarn’s ceiling paintedPlastered the ceiling of the barnPlastering the ceiling of the barnInstalled the Murphy bedMore gypsum boards in the barnThe lamps in the hallway were installedInstalled more lamp fixturesLight installationsSea container picked upSea container soldFinished cleaning the sea container

The west wall of the barn was paintedStarted preparing for painting the barnFinished plastered all walls of the barnStarted plastering the wallsBarn’s ceiling paintedPlastered the ceiling of the barnPlastering the ceiling of the barnInstalled the Murphy bedMore gypsum boards in the barnThe lamps in the hallway were installedInstalled more lamp fixturesLight installationsSea container picked upSea container soldFinished cleaning the sea container I moved from Sweden to The Netherlands in 1995.

I moved from Sweden to The Netherlands in 1995.

Here on this site, you find my creations because that is what I do. I create.